江西大森矿业有限公司

-

+86-18270853858

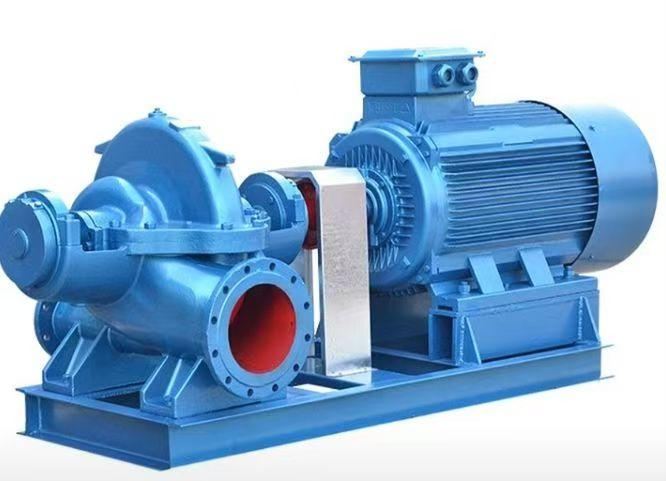

32CQ25 氰化物溶液泵

说明

1.基本规格

规格和型号:

32: inlet and outlet diameters (32mm)

CQ: magnetic drive centrifugal pump (leakage- free design)

25: rated flow rate (25m³/h)

Type: magnetic drive centrifugal pump (no shaft seal, leakage-proof)

Flow range: 15-30m³/h (adjustable)

Head: 25m (maximum up to 30m)

适用介质

cyanide solutions (such as sodium cyanide, potassium cyanide), acid and alkali corrosive liquids

2.结构设计

Material of flow-through

parts: Pump casing/impeller: 304/316L stainless steel (corrosion-resistant) or fluoroplastic lining (PTFE/ F46)

Isolation sleeve: Hastelloy or titanium alloy (anti-magnetic eddy current loss)

Sealing method: fully enclosed magnetic coupling transmission (zero leakage)

Bearing lubrication: medium self- lubrication (dry operation needs to be avoided)

3.动力和性能

Motor power: 1.1-2.2kW (380V/50Hz, explosion-proof motor Ex dⅡ BT4 can be equipped)

Speed: 2900r/min(standard)

Working pressure: ≤1.6MPa

Medium temperature:≤80℃ (high temperature type can reach 120℃)

Allowable particles: ≤0.1mm(pre-filter required)

4.Safety protection

Anti-leakage: no mechanical seal, to eliminate the risk of cyanide leakage

Explosion-proof option: Ex dⅡ BT4(suitable for flammable and explosive environment)

Overheat protection: motor temperature rise ≤75℃

automatic shutdown for overtemperature

5.设备尺寸和重量

Overall size: ≈500×300×400mm (length×width×height)

Machine weight: 50-80kg (depending on the material)

6.Maintenance points

No idling is strictly prohibited: bearings rely on medium lubrication, idling will cause damage

Regular inspection: Check the magnetic coupling for neutralization every 500 hours

Shutdown treatment: Immediately flush the pump cavity after conveying easy-to- crystallize Medium

选择建议

1. Highly corrosive working conditions (such as high-concentration cyanide liquid): Select perfluoroplastic lining or titanium alloy isolation sleeve models.

2. Explosion-proof requirements: Chemical workshops need to use explosion-proof motors + spark-free structures.

3. Supporting equipment: It is recommended to install a magnetic filter (to prevent iron filings from damaging the magnetic components). If need a cyanide corrosion resistance test report or a customized solution, please specify the specific medium concentration and working conditions.