Компания Jiangxi Dasen Mining Industry Co., Ltd.

-

+86-18270853858

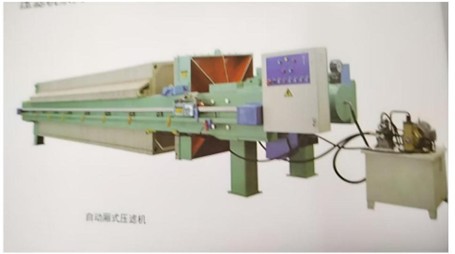

Пластинчато-рамный фильтр-пресс XM9002000U

ПАРАМЕТРЫ ПРОДУКТА

Технические параметры пластинчато-рамного фильтр-пресса XM9002000U

Описание

1.Основные характеристики

Анализ моделей

XM: фильтр-пресс камерного типа (X) (M - открытый поток, A - темный поток)

900: размер фильтровальной пластины (900 мм × 900 мм)

2000: Площадь фильтрации (2000 м2)

U: Может означать модернизированный или специальный материал

Количество фильтровальных камер: 80-120 (в зависимости от толщины и общей длины фильтровальной пластины)

Объем фильтровальной камеры: 3,5-5,5 м³ (объем обработки за один цикл)

Рабочее давление: 0,6-1,2 МПа (максимальное давление в гидравлической системе 1,6 МПа)

2.Структура и материал

Материал фильтрующей пластины:

Армированный полипропилен (PP), прорезиненное покрытие или чугун (на выбор)

Толщина: 60-80 мм (устойчивая к давлению конструкция)

Тип фильтровальной ткани:

Монофиламентный/мультифиламентный полиэстер (PE), полипропилен (PP) или нейлон (NMO)

Точность фильтрации: 550 мкм (в зависимости от выбора материала)

Конструкция рамы:

Углеродистая сталь Q235 (антикоррозийная краска) или нержавеющая сталь 304 (пищевой/химический класс)

3.Параметры работы

Возможности обработки:

Производительность по сухому материалу: 8-20 тонн/цикл (в зависимости от содержания твердого материала)

Концентрация корма: 30%-60% содержание твердого вещества (оптимальный диапазон 40%-50%)

Цикл фильтрации: 1,54 часа (включая уплотнение, подачу, отжим и выгрузку)

Содержание влаги в фильтровальном кеке: 15%-35% (может быть уменьшено путем вторичного прессования или сушки)

4.Система питания

Мощность гидравлической станции: 7,5-15 кВт (давление регулируется, с функцией поддержания давления)

Сила зажима: ≥3000 кН (для обеспечения герметичности)

Привод тяговой плиты: двигатель с регулируемой частотой (0,55-1,5 кВт) или пневматический (опция)

5.Функция автоматизации (опционально)

Управление с помощью ПЛК:

Автоматическое протягивание, выгрузка и очистка фильтровальной ткани

Защита от блокировки датчика давления/температуры

Системы помощи:

Устройство для промывки водой под высоким давлением (регенерация фильтровальной ткани)

Сушка сжатым воздухом (для уменьшения содержания влаги в фильтровальной лепешке)

6.размер и вес оборудования

Длина машины: ≈12-18 метров (в зависимости от количества фильтрующих пластин)

Вес: 25-40 тонн (тяжелее для моделей с чугунными фильтрующими пластинами)

Высота установки: ≥3,5 м (включая пространство для разгрузки)

7.Специальный дизайн (опционально)

Антикоррозийная модернизация: вся фильтрующая пластина из полипропилена + рамка из нержавеющей стали 316L (для сильной кислоты/щелочи)

Высокотемпературный тип: термостойкая фильтровальная пластина (≤120℃)

Взрывозащищенная конфигурация: Двигатель Ex dⅡ BT4 (химическая взрывобезопасная зона)

Ключевые соображения

1.Очки выбора:

Для материалов с высокой вязкостью (например, шлама) требуется высокопоточный и высоконапорный питательный насос

При содержании абразивных частиц рекомендуется использовать износостойкую фильтровальную ткань (например, нейлон).

2.Требования к техническому обслуживанию:

Проверяйте качество гидравлического масла каждые 500 часов

Рекомендуется заменять фильтровальную ткань каждые 3-6 месяцев (в зависимости от степени износа).

3.может обеспечивать быстрое открытие или энергосберегающие конструкции

Типичные сценарии применения

Горная промышленность: обезвоживание хвостов, фильтрация концентрата

Химическая промышленность: Диоксид титана, карбонат кальция твердо-жидкостное разделение

Охрана окружающей среды: обработка городских осадков, промышленных сточных вод

Более подробные параметры насоса подачи (например, подача плунжерного насоса 50 м³/ч) или проницаемость фильтровальной ткани зависят от данных о расходе, пожалуйста, укажите конкретные характеристики материала (например, размер частиц, значение pH).