Компания Jiangxi Dasen Mining Industry Co., Ltd.

-

+86-18270853858

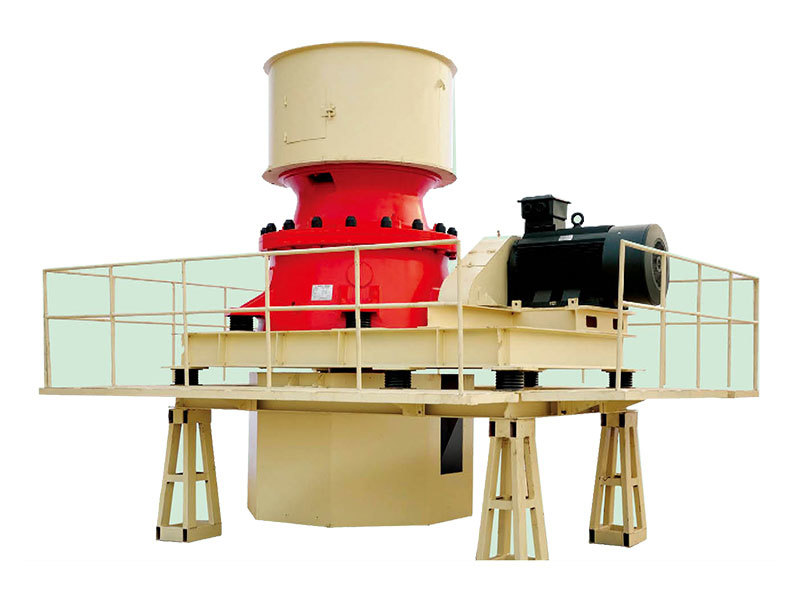

Одноцилиндровая гидравлическая конусная дробилка серии PYY

ПАРАМЕТРЫ ПРОДУКТА

Описание

This Cone Crusher is of the best combination of frequency and eccentricity that brings high content of fine-particle product; which requires less grinding and therefore helps reduce power consumption; more, a perfect-size crushing chamber suitable to the high frequency results in higher yield and better layer-on-layer crushing that helps produce consistent cubical-shape product.The Crusher is easy to operate and maintain with hydraulic protection, locking, regulation and chamber drainage. An optimal design contributes to seldom failure and a service factor more than 85%, and helps cut back the overall cost significantly.

1.1 Fine-particle crushed product that requires less grinding and therefore enhances subsequent grinding output and reduces power consumption of the system.

1.2 Optimal design and parameter setting that allows higher yield and fine product and therefore reduces cyclic load, which means less wearing of screen chutes and belt conveyors and also less power consumption with conveyors.

1.3 Easy-to-change liner that allows less downtime.

6.2 The crusher can be divided into finely and fractal in two forms.

Technical parameter of Single—cylinder hydraulic cone crusher (finely type)

| Model | Cavity | Materialinlet(mm) | Max size ofmineral admiteed(mm) | Minimum discharge(mm) | Minimum discharge(mm) | MotorPower(kw) | HostWeight(kg) | ||||

| Stroke | Stroke | Stroke | Stroke | Stroke | Stroke | ||||||

| PYY100 | 16 | 22 | 16 | 22 | 90 | 6000 | |||||

| A | 150 | 120 | 12 | 15 | 39 | 37 | |||||

| B | 130 | 105 | 10 | 11 | 33 | 31 | |||||

| C | 100 | 85 | 7 | 9 | 33 | 30 | |||||

| D | 40 | 32 | 5 | 6 | 31 | 29 | |||||

| PYY200 | 18 | 25 | 18 | 25 | 160 | 10600 | |||||

| A | 220 | 180 | 18 | 22 | 35 | 30 | |||||

| B | 150 | 120 | 15 | 19 | 35 | 30 | |||||

| C | 80 | 60 | 9 | 12 | 35 | 30 | |||||

| D | 40 | 32 | 6 | 8 | 35 | 30 | |||||

| PYY300 | 25 | 32 | 25 | 32 | 250 | 18500 | |||||

| A | 230 | 190 | 20 | 25 | 45 | 40 | |||||

| B | 150 | 125 | 17 | 20 | 45 | 40 | |||||

| C | 80 | 60 | 10 | 13 | 40 | 35 | |||||

| D | 40 | 32 | 6 | 8 | 40 | 35 | |||||

| PYY500 | 25 | 32 | 40 | 25 | 32 | 40 | 315 | 22500 | |||

| A | 230 | 180 | 22 | 26 | 30 | 50 | 45 | 40 | |||

| B | 150 | 125 | 19 | 22 | 26 | 48 | 43 | 38 | |||

| C | 100 | 80 | 12 | 14 | 16 | 40 | 35 | 30 | |||

| D | 50 | 40 | 8 | 10 | 12 | 30 | 25 | 20 | |||

| Model | Stroke | Tension side discharging mouth(mm) | |||||||||

| 8 | 12 | 16 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | ||

| PYY100 | 16 | 35-40 | 45-55 | 55-65 | 65-75 | 75-85 | 90-100 | 105-115 | |||

| 22 | 45-50 | 55-65 | 65-75 | 75-90 | 85-105 | 100-125 | 115-135 | ||||

| PYY200 | 18 | 65-75 | 75-90 | 85-105 | 100-125 | 135-150 | 160-175 | 170-190 | |||

| 25 | 90-110 | 110-130 | 125-155 | 160-180 | 185-210 | ||||||

| PYY300 | 25 | 100-120 | 110-135 | 130-160 | 150-180 | 170-200 | 200-230 | 230-260 | 350-290 | 270-310 | |

| 32 | 110-135 | 130-150 | 160-200 | 180-220 | 200-250 | 230-280 | 260-310 | 280-320 | 300-340 | ||

| PYY500 | 25 | 100-120 | 120-150 | 140-170 | 160-190 | 190-200 | 220-250 | 250-280 | 280-310 | 330-370 | 370-420 |

| 32 | 150-170 | 170-200 | 200-230 | 250-270 | 280-300 | 310-340 | 370-420 | 430-500 | |||

| 40 | 180-200 | 210-240 | 250-280 | 300-300 | 330-380 | 370-420 | 430-500 | ||||

Technical parameter of Single—cylinder hydraulic cone crusher (finely type)

| Model | Cavity | Materialinlet(mm) | Max size ofmineral admiteed(mm) | Minimum discharge(mm) | Minimum discharge(mm) | Motor Power(kw) | Host Weight(kg) | ||||

| Stroke | Stroke | Stroke | Stroke | Stroke | Stroke | ||||||

| PYY200 | 18 | 25 | 18 | 25 | 110-160 | 11800 | |||||

| A | 330 | 280 | 27 | 30 | 65 | 60 | |||||

| B | 250 | 210 | 25 | 28 | 60 | 55 | |||||

| PYY300 | 25 | 32 | 25 | 32 | 160-250 | 20000 | |||||

| A | 380 | 320 | 28 | 32 | 73 | 69 | |||||

| B | 280 | 240 | 26 | 30 | 66 | 62 | |||||

| PYY300 | 18 | 25 | 32 | 18 | 25 | 32 | 250-315 | 33000 | |||

| A | 500 | 420 | 50 | 55 | 60 | 80 | 75 | 70 | |||

| B | 380 | 320 | 40 | 45 | 60 | 70 | 65 | 60 | |||

| Model | Stroke | Tension side discharging mouth (mm) | ||||||||

| 35 | 40 | 45 | 50 | 55 | 60 | 65 | 70 | 75 | ||

| PYYZ200 | 18 | 160-190 | 180-210 | 200-230 | 230-250 | 350-270 | 270-300 | |||

| 25 | 190-240 | 210-260 | 230-280 | 260-310 | 290-340 | 310-370 | ||||

| PYYZ300 | 25 | 250-300 | 290-340 | 320-350 | 350-380 | 380-410 | 410-440 | 440-470 | ||

| 32 | 340-390 | 370-420 | 400-440 | 430-470 | 470-500 | 500-510 | 530-540 | |||

| PYYZ500 | 18 | 300-350 | 330-380 | 370-420 | 400-450 | 430-480 | 460-510 | 500-550 | ||

| 25 | 500-550 | 550-600 | 600-650 | 650-700 | 700-750 | 750-800 | ||||

| 32 | 650-700 | 700-750 | 750-800 | 825-875 | 900-950 | 950-1000 | ||||