Jiangxi Dasen Mining Industry Co., Ltd.

-

+86-18270853858

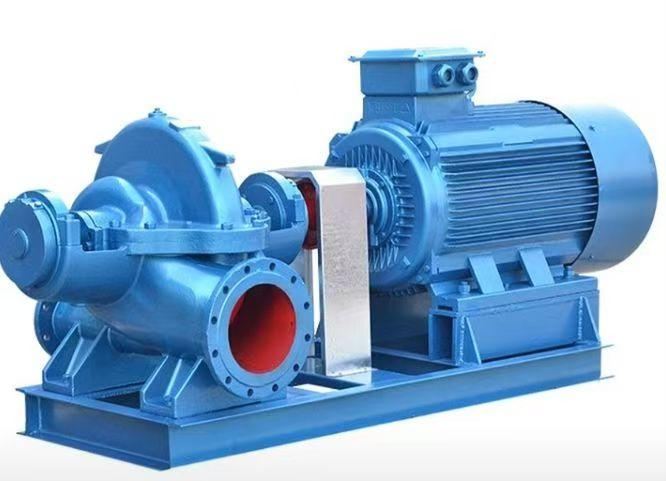

HZV65P sump pump

Description

1. Basic specifications

specifications and models:

HZV: may represent submersible (H) + vertical installation (Z) + special design (V)

65: discharge port diameter (65mm, DN65)

P: may represent cast iron material (P is cast iron, S is stainless steel, etc.)

Type: Submersible non-clogging sump pump

Maximum flow rate: 40-80m³/h (adjusted according to head)

Maximum head: 15-30m (higher head models can be customized)

2.Power and performance

Motor power: 7.5-15kW (380V/50Hz, explosion- proof optional)

Speed: 1450-2900r/min (4-pole/2-pole motor)

Allowable particle diameter: ≤50mm (fibrous impurities ≤20mm)

Medium temperature: ≤40℃(high temperature requires special design)

3.Structural design

Pump body material: Cast iron (HT250)/stainless steel (304/316L, corrosion-resistant)

Impeller type: Cyclone type/single-channel type (anti-winding, strong solid passing ability)

Sealing system: Double mechanical seal (SiC/graphite pairing)

Oil chamber leakage sensor (optional)

4.Applicable medium sewage type:

domestic sewage, industrial wastewater, mud containing solid particles pH range:

4-10 (corrosive media require stainless steel models)

Solid content:≤10% (weight ratio)

5. Intelligent control (optional)

Automatic start and stop: float switch/liquid level sensor control

Protection function: overload, phase loss, water leakage alarm (IP68 protection)

Dry running protection (sensor required)

6.Equipment size and weight

Outlet diameter: DN65 (flange standard GB/T 9119)

Machine weight: 120-180kg (cast iron/ stainless steel difference)

Maximum diving depth: ≤10m (depending on cable length)

Selection suggestions

1. Highly corrosive environment (such as chemical wastewater): choose 316L stainless steel impeller + mechanical seal nitrogen protection.

2. Containing fiber impurities:Preferentially use swirl impeller to avoid clogging.

3. Maintenance tips: Check the state of the sealing oil chamber every 500 hours. Long-

term out of use requires lifting and storage to prevent sediment solidification. If performance curve (QH) or explosion-proof certification documents are required, please specify the specific working conditions (such as sand content in the medium, operation cycle, etc.).