Jiangxi Dasen Mining Industry Co. Ltd.

-

+86-18270853858

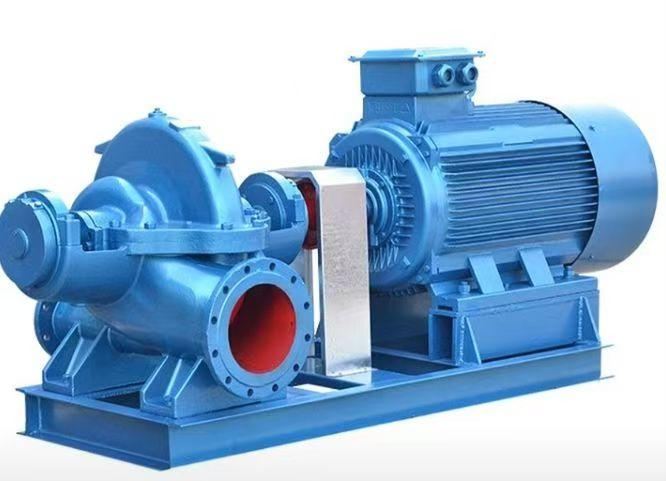

HZ200/150-SA thickener feed pump

Description

1. Basic specifications

model analysis:

HZ: chemical/heavy-duty centrifugal pump (H chemical, Z heavy-duty)

200/150: inlet and outlet diameters (200mm inlet/150mm outlet)

SA: special alloy (Super Alloy) lining or material code

Type: centrifugal slurry pump (designed for high-concentration slurry in thickeners)

Flow range: 300-600m³/h (slurry concentration 30%-50%)

Head: 20-40m (multi-stage series connection is possible)

2...Structural design

Material of flow-through parts:

Pump casing/impeller: high chromium alloy (Cr28, hardness ≥62HRC) or rubber lining (wear and corrosion resistant)

Shaft seal: double-end mechanical seal + flushing water system (adaptable to solid media)

Corrosion resistance: pH 2-12 (optional 316L stainless steel or fluorine- lined design)

3.Power and performance

Motor power: 75-160kW (frequency control, adapt to flow fluctuations)

Speed: 980-1480r/min (low speed reduces wear)

Allowable particle size: ≤10mm (grid filter required)

Working pressure:≤1.0MPa

4.Concentration process adaptability

Solid-liquid ratio adjustment: support 1:4~1:6 slurry transportation (refer to the solid-liquid ratio requirements of the concentrator) Anti-clogging design:

Large channel impeller (throughput capacity increased by 30%) Backwash interface (optional)

5.Safety and intelligent control

Monitoring system:

Bearing temperature vibration sensor (early warning fault)

Flow pressure interlock (linked with the concentrator)

Explosion-proof option: Ex dⅡ BT4 (flammable and explosive environment)

6.Equipment size and weight

7.Overall dimensions: ≈1800×1200×1500mm (length×width×height)

Machine weight: 1.5-2.5 tons (depending on the material)

Selection suggestions

1.High wear conditions (such as iron ore tailings): high chromium alloy impeller + ceramic liner is preferred.

2.Corrosive media (such as acidic slurry): full fluorine lining or 316L stainless steel pump body is used.

3. Points d'entretien :

Check lining wear every month (thickness <5mm needs to be replaced) Lubricate the sealing system every quarter (corrosion-resistant grease) If performance curves (QH) or material corrosion resistance test data are required, please specify the specific medium composition (such as Cl concentration, solid hardness, etc.).