Jiangxi Dasen Mining Industry Co. Ltd.

-

+86-18270853858

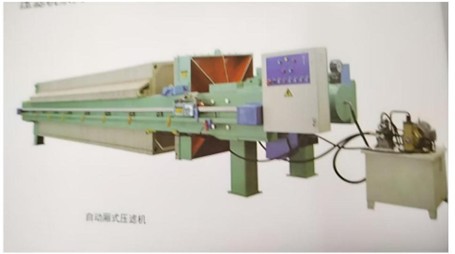

XM9002000U Plate and Frame Filter Press

PARAMÈTRES DU PRODUIT

XM9002000U Plate and Frame Filter Press Technical Parameters

Description

1. spécifications de base

Model Analysis

XM: Chamber type (X) filter press (M is open flow, A is dark flow)

900: filter plate size (900mm×900mm)

2000: Filtration area (2000 m2)

U: May stand for Upgraded or special material

Number of filter chambers: 80-120 (depending on the thickness and total length of the filter plate)

Filter chamber volume: 3.5-5.5m³ (single cycle processing volume)

Working pressure: 0.6-1.2MPa (maximum pressure of hydraulic system 1.6MPa)

2.Structure and material

Filter plate material:

Reinforced polypropylene (PP), rubber coated or cast iron (optional)

Thickness: 60-80mm (pressure-resistant design)

Filter cloth type:

Monofilament/multifilament polyester (PE), polypropylene (PP) or nylon (NMO)

Filtration accuracy: 550μm (depending on material selection)

Frame structure:

Carbon steel Q235 (anti-corrosion paint) or 304 stainless steel (food/chemical grade)

3.Performance parameters

Processing capabilities:

Dry material output: 8-20 tons/cycle (related to the solid content of the material)

Feed concentration: 30%-60% solid content (optimal range 40%-50%)

Filtration cycle: 1.54 hours (including compaction, feeding, squeezing, and unloading)

Filter cake moisture content: 15%-35% (can be reduced by secondary pressing or drying)

4.Power System

Hydraulic station power: 7.5-15kW (pressure adjustable, with pressure maintaining function)

Clamping force: ≥3000kN (to ensure sealing)

Pull plate drive: variable frequency motor (0.55-1.5kW) or pneumatic (optional)

5.Automation function (optional)

PLC Control:

Automatic plate pulling, unloading and filter cloth cleaning

Pressure/temperature sensor interlock protection

Assistance Systems:

High-pressure water washing device (filter cloth regeneration)

Compressed air drying (to reduce the moisture content of the filter cake)

6.Equipment size and weight

Machine length: ≈12-18 meters (depending on the number of filter plates)

Weight: 25-40 tons (heavier for cast iron filter plate models)

Installation height: ≥3.5 meters (including unloading space)

7.Special design (optional)

Anti-corrosion upgrade: all PP filter plate + 316L stainless steel frame (for strong acid/alkali)

High temperature type: heat-resistant filter plate (≤120℃)

Explosion-proof configuration: Ex dⅡ BT4 motor (chemical explosion-proof area)

Key Considerations

1.Selection points:

High-viscosity materials (such as sludge) require a high-flow, high-pressure feed pump

When containing abrasive particles, it is recommended to use wear-resistant filter cloth (such as nylon)

2.Maintenance requirements:

Check hydraulic oil quality every 500 hours

It is recommended to replace the filter cloth every 3-6 months (depending on wear and tear)

3.may provide quick-opening or energy-saving designs

Typical application scenarios

Mining: tailings dewatering, concentrate filtration

Chemical industry: Titanium dioxide, calcium carbonate solid-liquid separation

Environmental protection: municipal sludge, industrial wastewater treatment

More detailed feed pump parameters (such as plunger pump flow 50m³/h) or filter cloth penetration depend on rate data, please specify the specific material characteristics (e.g. particle size, pH value)