Jiangxi Dasen Mining Industry Co.

-

+86-18270853858

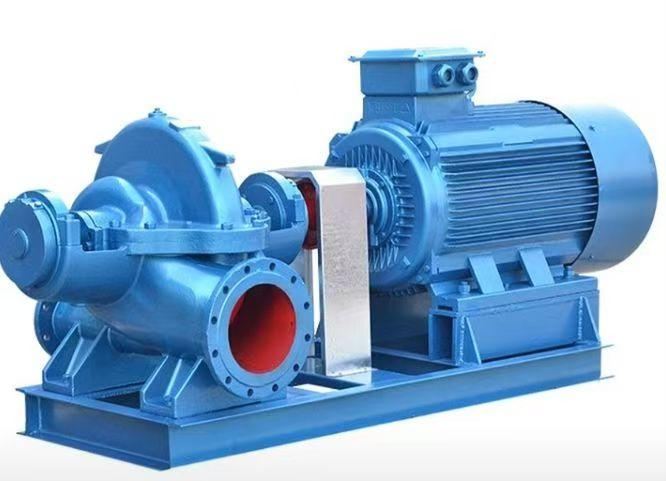

HZ150/100D-SA filtrate pump

Descripción

1.Basic specifications

Specifications and models:

HZ: may represent chemical special (H) + self-priming (Z)

150/100: inlet and outlet diameters (150mm inlet/100mm outlet)

D-SA: may be the material code (D cast iron, SA special alloy lining)

Type: centrifugal filtrate pump(suitable for filter media containing solid particles)

Flow range: 100-200m³/h Head: 20-50m (adjusted according to the impeller cutting situation)

2.Structural design

Material of flow-through parts:

Pump casing/impeller:high chromium alloy (Cr27, hardness ≥60HRC) or rubber lining (corrosion-resistant type)

Shaft seal: double-end mechanical seal (Si to graphite) + flushing water interface

Self-priming capacity: dry self-priming height ≥5m (vacuum auxiliary device is required)

3. Potencia y rendimiento

Motor power: 30-75kW (frequency conversion control is optional)

Speed: 1450-2900r/min (4-pole/2-pole motor)

Allowable particle size: ≤8mm (pre-filter required)

Working temperature: -20℃~120(℃high temperature type can reach 180℃)

4.Applicable medium filtrate type:

Mining filter press filtrate (containing trace solids) Chemical acid and alkali filtrate (pH2-12)

Viscosity range: ≤500cP (high viscosity requires special design)

5.Special configuration(optional)

Explosion-proof motor: Ex dⅡ BT4 (flammable and explosive environment)

Intelligent monitoring:

Bearing temperature vibration sensor

flow pressure interlock control system

6. Equipment size and weight

Overall dimensions: ≈1200×800×1000mm (length×width×height)

Machine weight: 500-800kg (depending on the material)

Recomendaciones de selección

1.Corrosive filtrate:Fully lined with fluorine or 316L stainless steel is preferred.

2. Containing hard particles: Wear- resistant impellers (such as tungsten carbide coating) are required.

3. Maintenance tips:

Check the wear of mechanical seals every month. If the pump is not used for a long time, the liquid in the pump must be drained

to prevent crystallization. If a performance curve (QH) or material corrosion resistance test report is required, please specify the specific medium composition (such as Cl concentration, solid content, etc.).