Jiangxi Dasen Mining Industry Co.

-

+86-18270853858

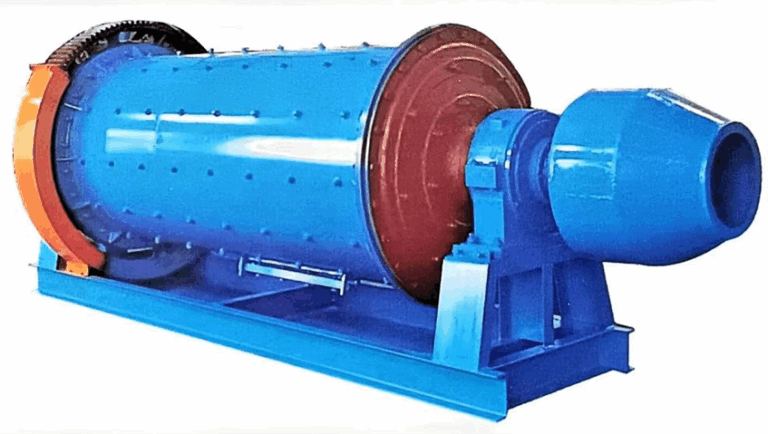

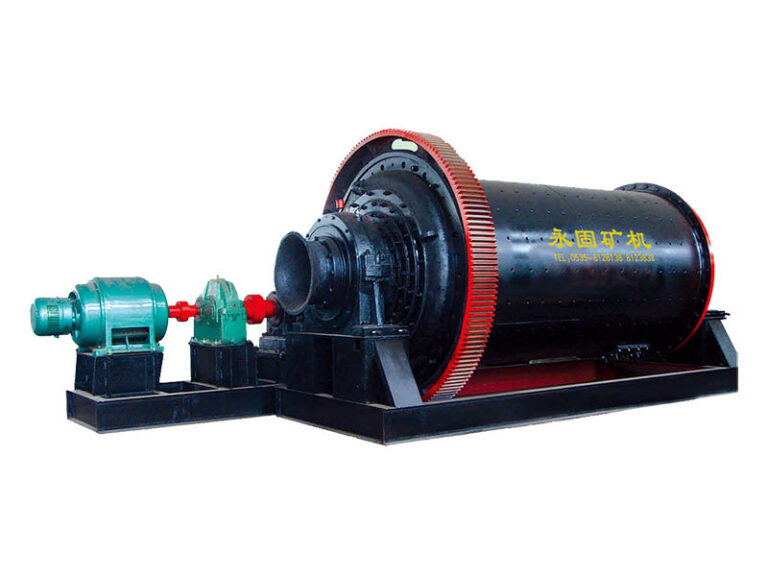

Molino de bolas MQG3640

Descripción

1. Basic Specifications

modelos:

MQG: Overflow ball mill (MQ is grid type, MQG is overflow type)

36: cylinder diameter (3600mm)

40: cylinder length (4000mm)

Effective volume: 30-32m³

Maximum ball loading: ≈60-70 tons (ball filling rate 25%-35%)

2. Processing capacity and particle size

processing capacity:

Wet grinding:30-75 tons/hour (adjusted according to material hardness, feed size and finished productfineness)

Dry grinding: slightly lower than wet grinding, and needs to be combined with an air selection system

Feed size: 25mm (20mm is recommended to improve efficiency)

Discharge size: 0.074-0.4mm (adjustable, controlled by grinding medium ratio)

3. Power system

Main motor power: 800-1000kW (usually high-voltage motors, such as 10kV/ 6kV, depending on the configuration)

Reducer model: such as JS140, MBY800 and other hard- toothed reducers

Cylinder speed: 17-19r/min (70%-80% of the critical speed)

4.Structural design

Cylinder material: Q235B or Q345B steel plate, thickness ≥40mm

Liner type: high manganese steel (ZGMn13), rubber or composite liner (wear-resistant life is about 6-12 months)

Bearing type: large double-row spherical roller bearing (or sliding bearing, forced lubrication required)

5.Applicable materials

Metal ore: iron ore, copper ore, gold ore, etc. Ore dressing and grinding

Non-metallic ore: quartz sand, feldspar, fluorite,etc. Ultra-fine powder processing

Industrial field: cement clinker, slag powder, chemical raw materials

6.Tamaño y peso del equipo

Machine weight: ≈90-120 tons (including motor, reducer and basic frame)

Overall dimensions (length × width × height): ≈12m × 5.5m × 4.5m (including transmission device)

7. Configuración opcional

Automation control: PLC system monitoring current, temperature, vibration, interlocking protection

Environmental protection measures: supporting dust removal equipment (pulse bag dust collector), sound insulation cover (noise ≤85dB)

Lubrication system: automatic centralized lubrication (main bearing, gear meshing parts) Notes

1.MQG3640 may vary in motor power and liner material, and the specific model suffix needs to be confirmed.

2.Key factors for grinding efficiency:

Steel ball/steel segment ratio (usually 40-120mm in diameter) Material hardness (Mohs hardness ≤7.5 is appropriate) Slurry concentration (60%-75% is recommended for wet grinding)

3.Maintenance focus: Regularly check the gear meshing clearance, liner bolt looseness and lubrication system oil pressure. detailed motor model, reducer speed ratio or basic installation diagram depend on specific application scenarios (such as ore dressing plant, cement plant, etc.).