Jiangxi Dasen Mining Industry Co., Ltd.

-

+86-18270853858

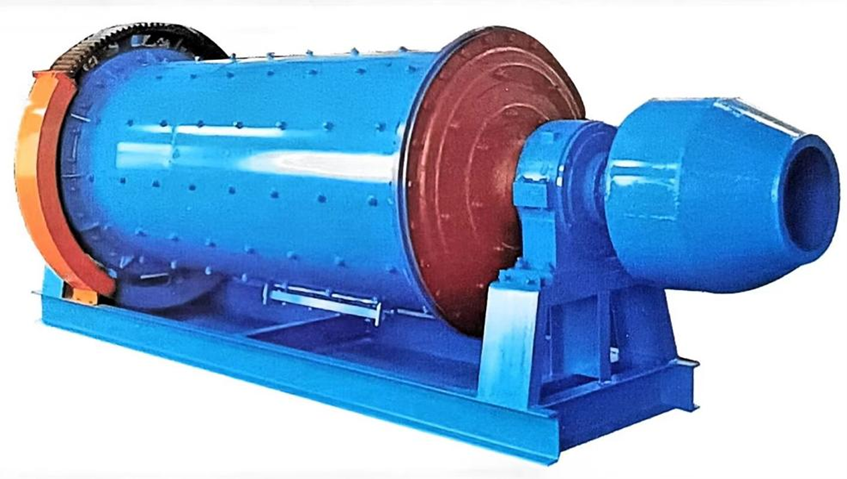

MQY3645 ball mill

Description

1.Basic specifications

models:

MQY: Overflow ball mill (M mill, Q light, Y overflow discharge)

3645: cylinder diameter 3600mm × length 4500mm

Type: Wet overflow ball mill (two-bin structure)

Design standard: GB/T 257082010 (mining machinery standard)

- Performance parameters

| parameter | index |

| Effective volume | ≈3840m³ |

| Maximum ball loading capacity | 75-85 tons (filling rate 25% -35%) |

| processing capacity | 40-90 tons/hour (adjusted according to materials) |

| Feed particle size | ≤ 25mm (recommended ≤ 20mm) |

| Discharge size | 0.074-0.5mm (adjustable) |

| rotational speed | 16-18r/min (critical speed 75%) |

3. Power system

Main motor power: 1000-1250kW (high-voltage motor, 6kV/10kV)

Reducer model: JS150/MBY1000 (hardened tooth surface, transmission efficiency ≥96%) Starting method: liquid soft start or frequency conversion control

4.Structural design

Cylinder material: Q345B steel plate (thickness ≥50mm)

Liner type: high manganese steel (ZGMn13Cr2, life 812 months)

Rubber lining (noise reduction, suitable for wet method)

Bearing system:

double-row spherical roller bearings (or hydraulic static sliding bearings)

Lubrication method: high-pressure thin oil station circulation lubrication

5.Applicable materials and industries

Metal ores: second/third stage grinding of gold, copper and iron ore

Non-metallic ores: quartz sand, apatite ultrafine grinding

Industrial field: cement clinker, slag powder

6. Equipment

| parameter | numerical value |

| External dimensions | ≈14m×6m×5m |

| Whole machine weight | ≈ 110-140 tons |

7. Energy saving and intelligent configuration (optional)

Energy saving design: Comprehensive power saving 20% (compared with traditional ball mill) Automation control: PLC monitoring current, temperature, vibration, interlock protection

Selection suggestions

1. High hardness ore (such as iron ore): It is recommended to configure the power ≥1250kW,

and the liner should be made of high chromium alloy.

2. Corrosive media: Choose 316L stainless steel components or rubber lining.

3. Maintenance points:

Check the gear meshing clearance every 500 hours

Replace the bearing lubricant every 3000 hours If need a performance curve (QH) or wear test report, please explain the specific working conditions (such as ore hardness, grinding concentration, etc.).